Grade B lithium cells, also known as recycled lithium power cells, retain 60-80% of their original capacity and are crucial for resource circularity but face significant challenges. While reusing them in energy storage or recovering their metals contributes to sustainability, about 70% of these used lithium cells in China enter illegal workshops. This reduces efficiency and poses a threat to ecological safety. This analysis explores the dilemma in China’s Grade B lithium battery cells market, risks of informal recycling and sustainable solutions.

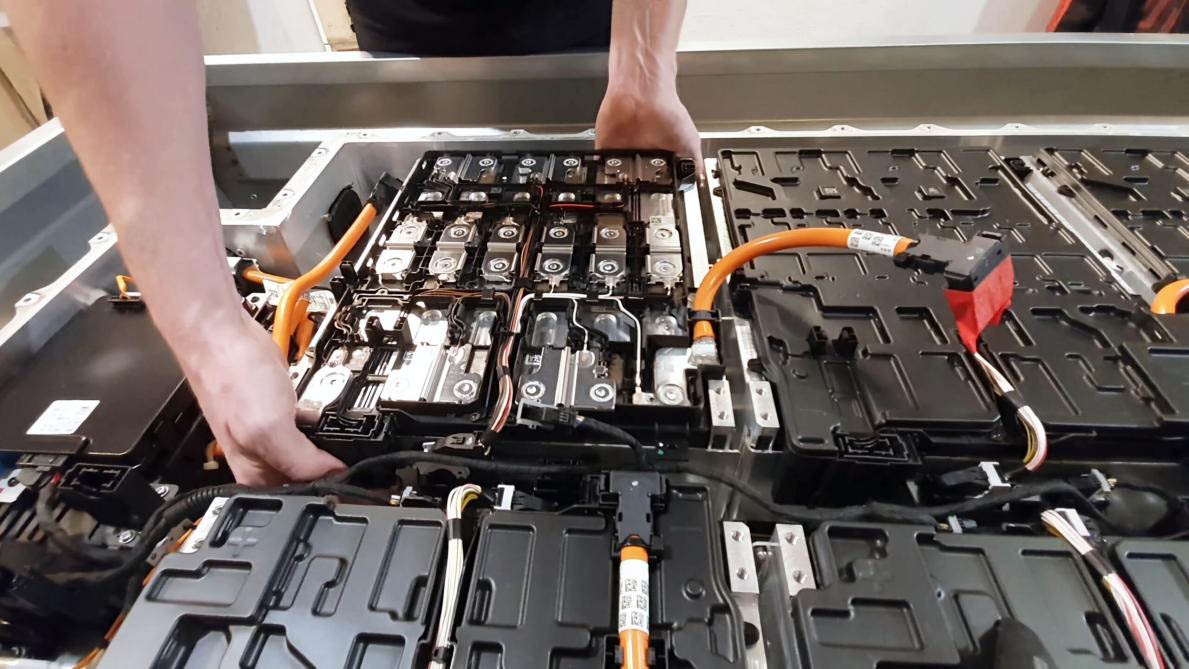

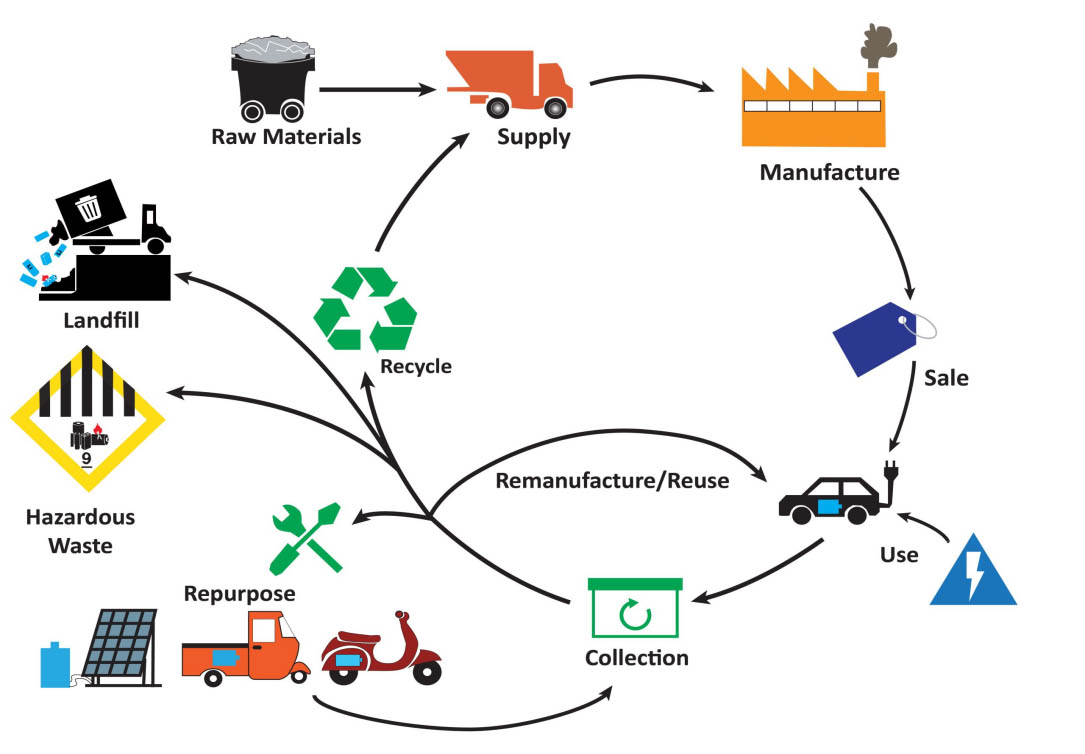

Recycling retired lithium EV batteries (Grade B battery cells) is crucial for resource sustainability and environmental protection. When battery capacity degrades to 60%, automotive factories conduct professional disassembly and restructuring to repurpose recycled cells for solar energy storage systems, logistics vehicles, and other applications through cascading utilization.

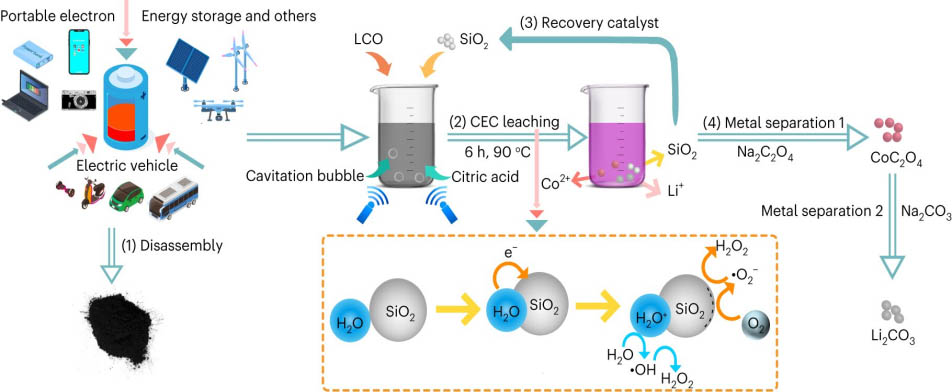

For batteries unfit for secondary use, advanced extraction techniques recover critical metals like lithium, nickel, and cobalt, regenerating them into raw battery materials to achieve resource circularity.

Discount Coefficients & Recycling Efficiency

The residual value of retired lithium ion batteries (discount coefficient) varies based on condition.

- 1. Electrolyte-injected batteries: 30%-50% discount coefficient due to contamination risks.

- 2. Non-electrolyte-injected batteries: Achieve the discount coefficients to 60-80%, as uncontaminated cathode/anode materials allow 95%+ metal recovery rates.

Illegal Recycling Channels Threaten Sustainability

Currently, about 70% of used EV batteries are diverted to unregulated markets. Small-scale workshops without licenses or environmental certifications exploit low operational costs to outbid compliant recycle lithium batteries company. These operations bypass taxes, safety protocols, and eco-friendly processes, prioritizing short-term profit over sustainability.

Environmental & Economic Risks of Informal Recycling

- ▲ Inefficient Material Recovery: Crude methods (e.g., burning, acid leaching) yield <50% metal recovery rates vs. >90% in certified facilities using hydrometallurgy or vacuum pyrolysis

- ▲ Pollution Hazards: Electrolyte Leakage and toxic emissions (e.g., hydrogen fluoride, heavy metals) Contaminate the soil/water.

- ▲ Market Disruption: Refurbished or poorly processed lithium-ion deep cycle batteries re-enter markets, raising safety risks and undermining circular economy goals.

This unregulated chain wastes critical resources while threatening ecosystems and public health. Establishing formal recycling channels remains crucial for sustainable EV development.

To address chaotic lithium battery recycling practices, we need a comprehensive system that combines legal oversight, market incentives, and tech solutions:

- ⭐ Laws: Speed up legislation to ensure full-chain tracking and set dynamic pricing linked to metal futures, supported by tax breaks.

- ⭐ Industry Standards: Raise entry barriers to eliminate unqualified players and strengthen cross-region enforcement with public oversight tools.

- ⭐ Innovation: Fund eco-friendly recycling tech and balance market risks via early warnings.

This approach aims to boost formal recycling rates from 30% to over 85%, creating a sustainable industry that benefits both resource recycling and environmental protection.

Conclusion

The Grade B battery debate reflects a clash between short-term gains and sustainable growth. While recycled Grade B lithium-ion cells may appear cost-effective due to their discounted pricing (30%-80% residual value), their affordability often stems from hazardous shortcuts: illegal workshops bypass safety protocols, evade taxes, and employ crude recycling methods that recover <50% of critical metals. This not only wastes finite resources but risks severe consequences—toxic pollution, fire hazards from unstable refurbished batteries, and long-term ecosystem damage.

That’s why there are so many cheap lithium battery storage on the market now. For businesses, prioritizing cheaper Grade B LiFePO4 battery cells is a false economy. Substandard cells derived from unregulated recycling channels undermine system reliability and expose users to legal and reputational liabilities. In contrast, Grade A battery cells—produced under strict quality controls with traceable raw materials—ensure >95% metal recovery rates in formal closed-loop systems, maximizing both safety and lifecycle value.

The path forward is clear: Raising Grade A cell yields (currently 87%) and enforcing strict recycling regulations will drive industry progress. Choosing compliant lithium battery suppliers is not merely a business decision; it represents a commitment to environmental stewardship and operational safety. This choice ensures that companies align with sustainable practices while safeguarding their operations from potential risks. By rejecting substandard alternatives and investing in certified Grade A solutions, stakeholders secure sustainable returns while safeguarding ecosystems and public health.

Post time: May-14-2025